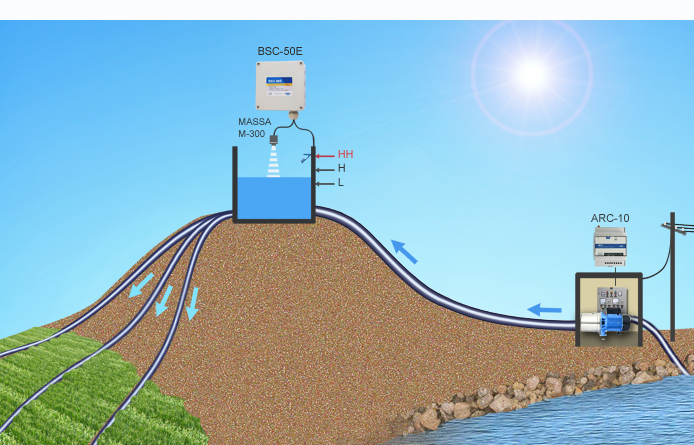

The water level regulation of a reservoir, used for irrigation purposes, is the requirement for an M2M control system. The reservoir is located in an off-grid area, on a hill. A pump house located below the hill, feeds the reservoir from a near river. The system is shown in the figure below.

Proposal

A BSC-50E battery powered RTU with an ultrasonic sensor, is used for tracking the reservoir water level. BSC-50E sends M2M commands to an ARC-10 GSM controller, which controls the pump operation through its relay outputs. The pump automation system (e.g. a PLC) supports the following functions:

| Function | Actuator / Indicator | Action |

|---|---|---|

| Start Operation | Push button (Start button) | Enable Remote control, Turn Pump ON for t=T1 1) |

| Stop Operation | Push button (Stop button) or Digital input IN1 |

High pulse on IN1–> Cancel system operation |

| Remote Control | Digital input IN2 | High to Low transition –> Turn Pump ON for t=T2 2), Low to High transition –> Stop PUMP) |

| Thermal protection | Digital output OUT1 | Low –> Normal operation, High –> Protection active (Operation cancelled) |

1) T1 is the time, depending on the pump flow rate, needed to fill the reservoir from empty state to a level between H and HH.

2) T2 is the time it takes to reach a level between H and HH, starting with water level L.

ARC-10 outputs DO1, DO2 are connected to IN1 and IN2 of the pump control system respectively. The thermal protection indication (OUT1) is connected to ARC-10, digital input 1 (DI1).

On the other side, an ultrasonic sensor (Massa M300) is connected to BSC-50E, analog input 1 (AI1). Two alarm limits are set on the analog measurement:

- Alarm limit low, which corresponds to level L.

- Alarm limit high, which corresponds to level H.

The water level is logged every hour. A level switch, indicating the HH water level, is connected to BSC-50E, digital input 1 (DI1).

Operation description

After start up, the pump feeds the reservoir, until the water level reaches the high limit (Level H). In the meantime BSC-50E scans the water level every minute.

On reaching the high limit, BSC-50E sends an M2M SMS, commanding the ARC-10 unit to switch DO2 on. The pump is turned off. At the same time, BSC-50E switches level scanning to a lower rate (e.g. every 15 minutes), to save power.

The pump remains in the hold state until the water level drops, due to irrigation flow, below the low limit. Then BSC-50E sends an SMS, commanding the ARC-10 unit to switch DO2 off. The pump is turned on. At the same time, it switches to higher sampling rate (every minute) to keep track of the reservoir filling.

Once a day, BSC-50E sends the water level logs to a system administrator.

Alerting

If the water level reaches, for any reason, the HH limit, the level switch activates an alarm on BSC-50E, DI1. BSC-50E sends an SMS command to the ARC-10 unit, to switch DO1 on for 2 seconds. The feeding system operation is cancelled. An additional SMS is sent to maintenance personnel, alerting for the malfunction.

In case of pump overheating, ARC-10 sends a respective alert to maintenance personnel.

Battery lifetime

The lifetime of the BSC-50E internal battery (LSH-20) depends on the water feeding cycles per day, as shown in the table below:

| Feeding cycles | M2M SMS | Daily consumption [mAh] | Battery Lifetime [Years] |

|---|---|---|---|

| 2 | 4 | 16.7 | 2.13 |

| 4 | 8 | 20.2 | 1.76 |

| 6 | 12 | 24.6 | 1.44 |

| 8 | 16 | 31.0 | 1.14 |

| 10 | 20 | 37.4 | 0.95 |

Read more at,